Mes has provided independent materials testing, failure analysis, INSPECTION, and engineering consulting services for over 40 years.

OUR TYPICAL PROJECTS INCLUDE

Metallurgical Engineering Services offers quality testing, modern equipment, an experienced staff, and rapid turnaround.The professional staff consists of doctorate level and experienced professionals in the disciplines of materials science, electron beam surface characterization, weld inspection, mechanical, and metallurgical engineering, where we focus on:

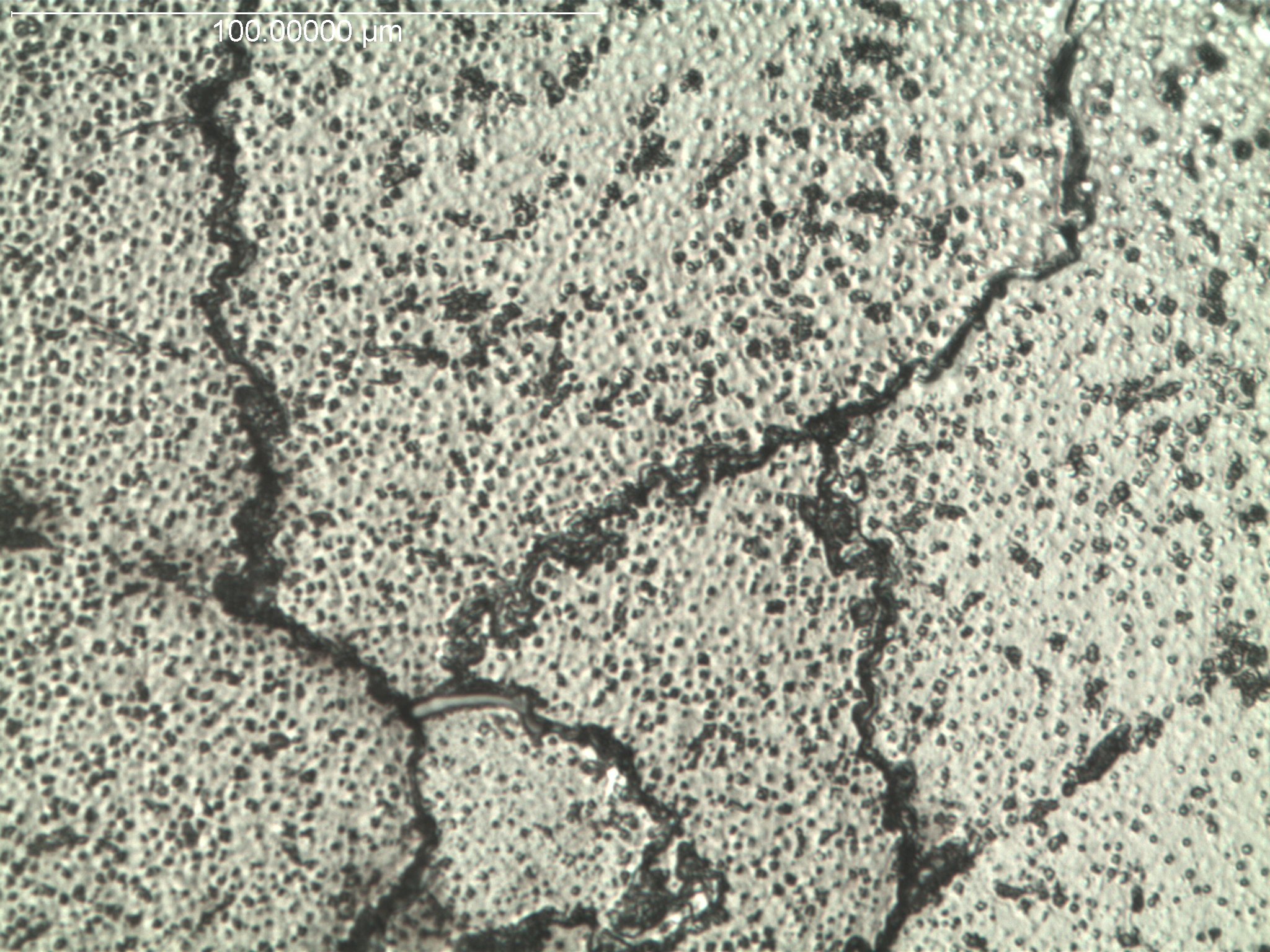

Failure analysis of components and systems

Mechanical testing and chemical analysis of all materials

Field inspection of large metal systems

Paint and coating testing

Welder and Weld Procedure Certification

Environmental exposure testing

We perform ASTM, ISO, MIL, and AWS standard tests for a variety of materials. With our primary lab located in the Dallas metroplex, we provide services to all industries worldwide. Our flexible services allow us to offer rapid, 24-hour turnaround. We encourage you to apply our teamwork to your most difficult challenges and enjoy the benefits of our specialized services.